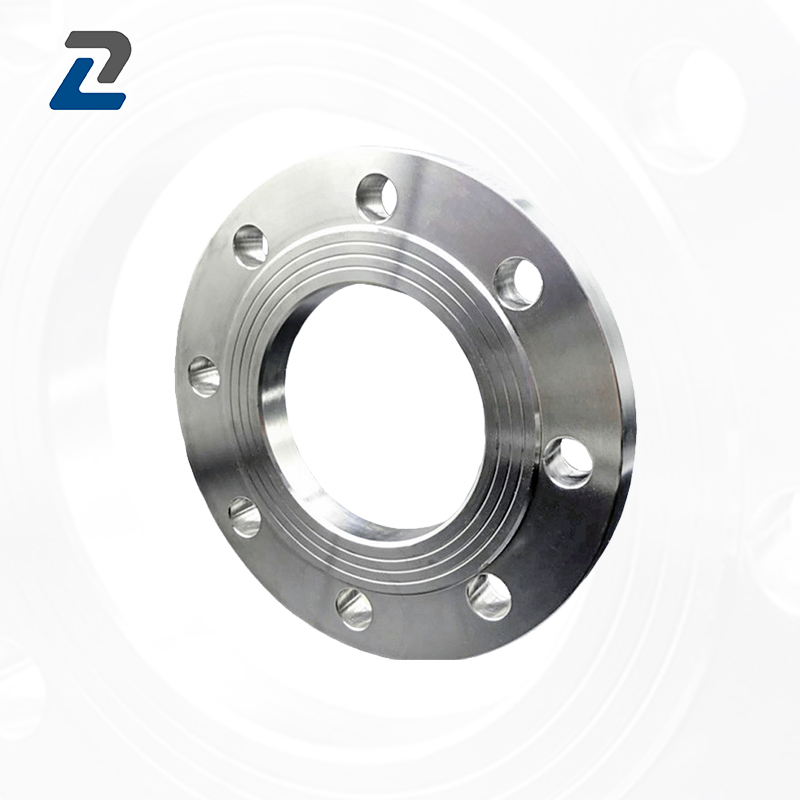

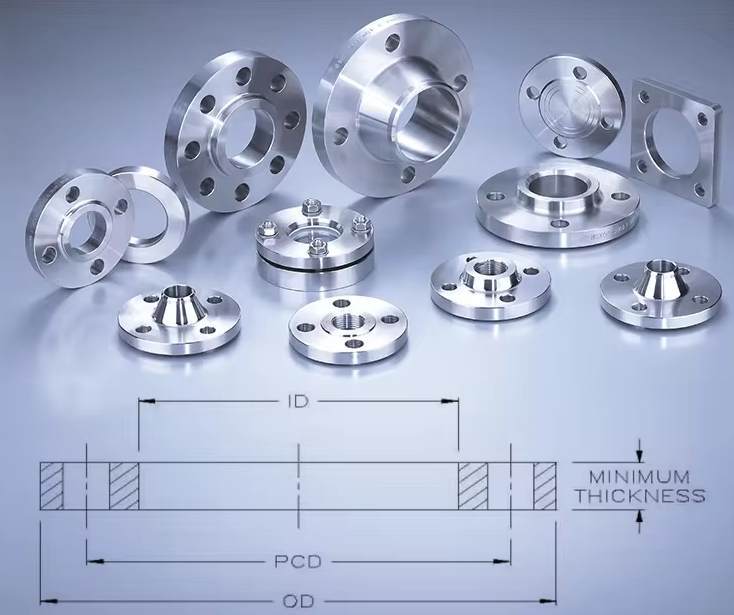

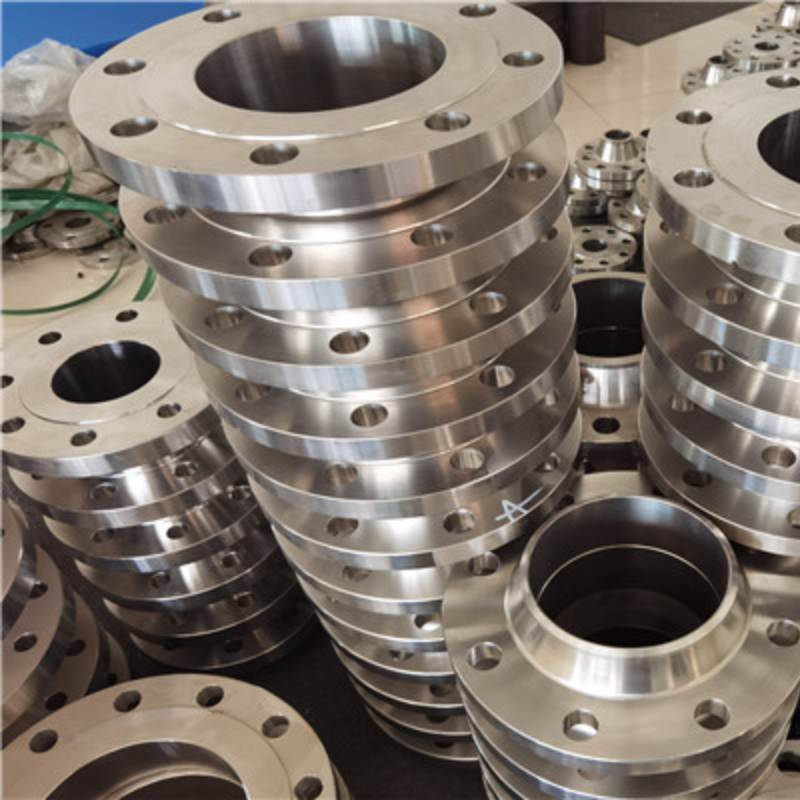

Stainless steel flange is a common component for connecting pipes, which is widely used in chemical, petroleum, pharmaceutical, food and other fields. It can connect two pipes and play a sealing role. Stainless steel flange has the characteristics of simple construction, easy use and reliable sealing, so it is widely used in various industrial fields.

Product Parameters

| Product name | Stainless steel pipe flange |

| Standard | ANSI, bs, DIN, GB, ISO, JIS, Jpi, ASME |

| Material | SS304L, SS316L, SS304, SS201 ect. |

| Certification: | ISO9001,ISO14001,ISO45001 |

| Connection type | Raised Face, Flat Face, Ring Type Joint, Lap-Joint Face, Large Male-Female, Small Male-Female,Large tongue groove, Small tongue groove etc |

| Woking pressure: | ≤1.6 Mpa |

| Temperature Range: | -10degree to +150degree |

| Tolerance: | ± 1% |

| Design: | OEM & ODM |

| Thickness | SCH5-SCH160 |

| Size | 1/2′ ~ 48′ |

| Type | Butt Welded |

| Surface Treatment: | Pickled surface/Ground polished surface |

| Application | It is usually used in constructions,petroleum, chemical industry, power, ship building, paper making, metallurgy, water supply and sewage work, light and heavy industry, plumbing and electric etc. |

| Package |

Standard export wooden case or as you requested |

Product Specifications

|

Steel Flanges EN1092/ISO7005 |

||||||||

|

Pipe Size |

DN |

PN |

OD |

PCD |

ID |

Bolt No. |

Bolt Hole Dia |

Thickness |

|

50 |

40 |

16 |

150 |

110 |

55 |

4 |

18 |

18 |

|

63 |

50 |

16 |

165 |

125 |

68 |

4 |

18 |

20 |

|

75 |

65 |

16 |

185 |

145 |

80 |

4 |

18 |

20 |

|

90 |

80 |

16 |

200 |

160 |

95 |

8 |

18 |

20 |

|

110 |

100 |

16 |

220 |

180 |

116 |

8 |

18 |

22 |

|

125 |

125 |

16 |

250 |

210 |

130 |

8 |

18 |

22 |

|

140 |

125 |

16 |

250 |

210 |

150 |

8 |

18 |

22 |

|

160 |

150 |

16 |

285 |

240 |

170 |

8 |

22 |

24 |

|

180 |

150 |

16 |

285 |

240 |

188 |

8 |

22 |

24 |

|

200 |

200 |

16 |

340 |

295 |

210 |

12 |

22 |

26 |

|

225 |

200 |

16 |

340 |

295 |

235 |

12 |

22 |

26 |

|

250 |

250 |

16 |

405 |

355 |

265 |

12 |

26 |

29 |

|

280 |

250 |

16 |

405 |

355 |

290 |

12 |

26 |

29 |

|

315 |

300 |

16 |

460 |

410 |

335 |

12 |

26 |

32 |

|

355 |

350 |

16 |

520 |

470 |

365 |

16 |

26 |

35 |

|

400 |

400 |

16 |

580 |

525 |

420 |

16 |

30 |

38 |

|

450 |

450 |

16 |

640 |

585 |

470 |

20 |

30 |

42 |

|

500 |

500 |

16 |

715 |

650 |

520 |

20 |

33 |

46 |

|

560 |

600 |

16 |

840 |

770 |

575 |

20 |

36 |

55 |

|

630 |

600 |

16 |

840 |

770 |

650 |

20 |

36 |

55 |

|

710 |

700 |

16 |

910 |

840 |

740 |

24 |

36 |

63 |

|

800 |

800 |

16 |

1025 |

950 |

830 |

24 |

39 |

74 |

| Steel Backing Ring ANSI B16.5 | |||||||

| Pipe Size | DN | OD | PCD | ID | Bolt No. | Bolt Hole Dia | Thickness |

| 50 | 1 1/2″ | 127 | 98.6 | 63 | 4 | 16 | 17.5 |

| 63 | 2″ | 152 | 120.5 | 68 | 4 | 20 | 19.5 |

| 75 | 2 1/2″ | 178 | 139.5 | 80 | 4 | 20 | 22.5 |

| 90 | 3″ | 190 | 152.5 | 95 | 4 | 20 | 24 |

| 110 | 4″ | 229 | 190.5 | 116 | 8 | 20 | 24 |

| 125 | 5″ | 254 | 216 | 130 | 8 | 22 | 24 |

| 140 | 5″ | 254 | 216 | 150 | 8 | 22 | 24 |

| 160 | 6″ | 279 | 241.5 | 170 | 8 | 22 | 25.5 |

| 180 | 6″ | 279 | 241.5 | 188 | 8 | 22 | 25.5 |

| 200 | 8″ | 343 | 298.5 | 210 | 8 | 22 | 29 |

| 225 | 8″ | 343 | 298.5 | 235 | 8 | 22 | 29 |

| 250 | 10″ | 406 | 362 | 265 | 12 | 26 | 30.5 |

| 280 | 10″ | 406 | 362 | 290 | 12 | 26 | 30.5 |

| 315 | 12″ | 483 | 432 | 335 | 12 | 30 | 32 |

| 355 | 14″ | 533 | 476 | 365 | 12 | 26 | 35 |

| 400 | 16″ | 597 | 540 | 420 | 16 | 30 | 37 |

| 450 | 18″ | 635 | 578 | 470 | 16 | 33 | 40 |

| 500 | 20″ | 698 | 635 | 520 | 20 | 33 | 43 |

| 560 | 24″ | 813 | 749.5 | 575 | 20 | 36 | 48 |

| 630 | 24″ | 813 | 749.5 | 650 | 20 | 36 | 48 |

| 710 | 28″ | 927.1 | 863.6 | 740 | 28 | 35 | 52.4 |

| 800 | 32″ | 1060.4 | 977.9 | 830 | 28 | 41 | 57.1 |

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

Applications

Product Packaging

Product Transportation